|

INSTALLATION GUIDE

TABLE OF

CONTENTS

Important safety hints

I. How to install your fence charger

II. Operating instructions for solar installation

III. How electric fencing works

IV. Trouble shooting guide

V. Radio & television interference

VI. Lightning & surge protection

VII. Helpful fence building hints

IMPORTANT SAFETY HINTS!

| 1. |

To reduce risk of electrical shock do not remove

CAUTION cover. Refer to service personnel. |

| 2. |

Never electrify barbed wire! The barbs may

injure animals if they become tangled in the fence. |

| 3. |

Use "1 amp/250V" fuses only. If fuses higher

than 1 amp or lower than 250V are used, they can damage

a fence controller and void your warranty. Fence

controllers that are protected with replaceable fuses

use external fuse holders. If there is no external fuse

holder,

there is no fuse to replace. |

| 4. |

Always disconnect battery-powered fence

controllers from the battery before recharging the

battery. Failure to do so may damage your fence

controller and battery charger, and void your warranty. |

| 5. |

Never run more than one fence controller on

the same fence line at one time. The pulses of short

shock solid state fence controllers will be too close

together and may be hazardous to animals and people. It

will also damage your fence controllers. |

| 6. |

Never alter the design of a fence controller

or substitute components. This could be hazardous

to you and will void the warranty. |

| 7. |

Instruct all persons how to disconnect a fence

controller in case of emergency. Post signs on electric

fences along public roads or near residences. |

| 8. |

Never disconnect wires or approach a fence

during lightning storms. |

| 9. |

"WARNING" Risk of electric shock! Do not

connect an electric fence to any other device such as a

cattle trainer or a poultry trainer. Otherwise lightning

striking your fence will be conducted to all other

devices. |

| 10. |

To reduce the risk of electric shock, an AC line

operated fence controller has a polarized plug (one

blade is wider than the other). This plug will fit in a

polarized outlet only one way. If the plug does not fit

fully in the outlet, reverse the plug, if it still does

not fit, contact a qualified electrician to install the

proper outlet. Do not change the plug in any way. |

| 11. |

Never connect a DC fencer to an AC power

supply. |

| 12. |

Always check your fencer and fence line for

voltage once installation is complete. The fence OK

light will flash when power is on the fence. The fencer

OK light operates continuously with the continuous

current fencers that are equipped with lights. |

INSTALLATION

AND OPERATING

YOUR FENCE CONTROLLER

THE SEVEN SINS OF

FENCE CONTROLLER INSTALLATIONS

|

1. |

An insufficient ground system

for the fence controller. (Refer to Step 2 of the

installation instructions.) |

|

2. |

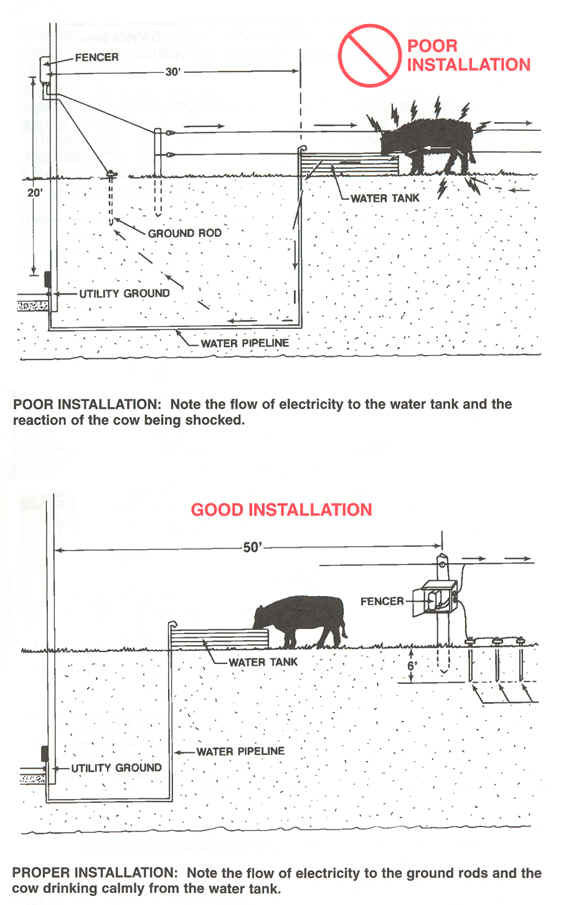

Stray voltage may occur when the

fence controller ground system is located within 50

ft. of a utility ground, buried water pipe, or

buried telephone wire. (Refer to Step 2 of the

installation instructions and Radio Interference

Section.) |

|

3. |

Inadequately insulated lead-out

wire and jumper wires (wire must be insulated to 20,000V

minimum). (Refer to Step 1 of the installation

instructions.) |

|

4. |

The ground wire is not adequately

insulated and is located 20 ft. or more from fence

controller. (Refer to Step 2 of the installation

instructions.) |

|

5. |

Inferior connections and splices

of the fence wire, ground wire, lead-out wire, and

jumper wires. (Refer to Step 3 of the installation

instructions.) |

|

6. |

Substandard fence wire insulation:

cracked insulators, poor quality insulators, water hose,

plastic tubing, or the use of wood posts without

insulators. (Refer to Step 3 of the installation

instructions.) |

|

7. |

The fence controller is underpowered

for the condition of the fence being energized (i.e.,

rain, snow, ice, vegetation, rusty wire, and length of

fence). (Refer to "How Electric Fencing

Works" in this manual.) |

I. HOW TO

INSTALL

YOUR FENCE CONTROLLER

Grounding Instructions: This controller must

be grounded. If it should malfunction or break down, grounding

reduces the risk of electrical shock by providing a path of low

resistance for the electric current. AC line operated

controllers are provided with a polarized 2-blade attachment

plug for use on a 120-volt circuit. The plug must be inserted

into an appropriate outlet that is properly installed in

accordance with all local codes and ordinances.

Grounding of this product is provided by a properly installed

ground rod electrically connected to the fence controller output

ground terminal. An internal fault on an improperly grounded

fence controller could result in a risk of high electric shock

currents on the electrified fence.

DANGER - For an AC line operated fence controller, do not

modify the plug provided with the controller if it will not fit

the outlet; have a proper outlet installed by a qualified

electrician. If it is necessary to use an extension cord, use

only a polarized extension cord that will accept the plug for

the unit. Repair or replace a damaged cord.

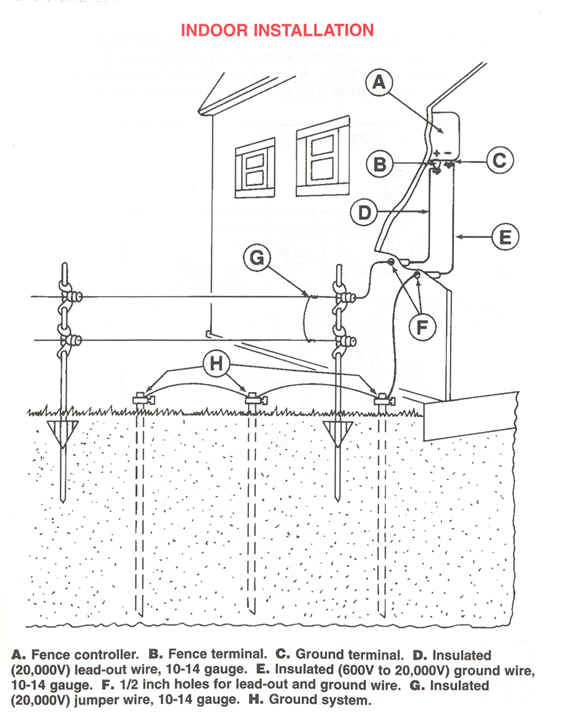

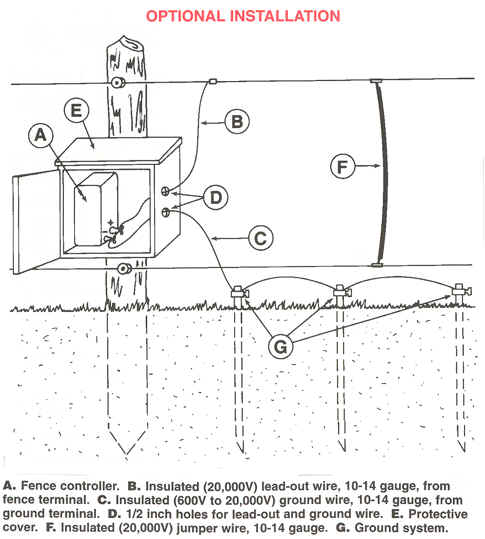

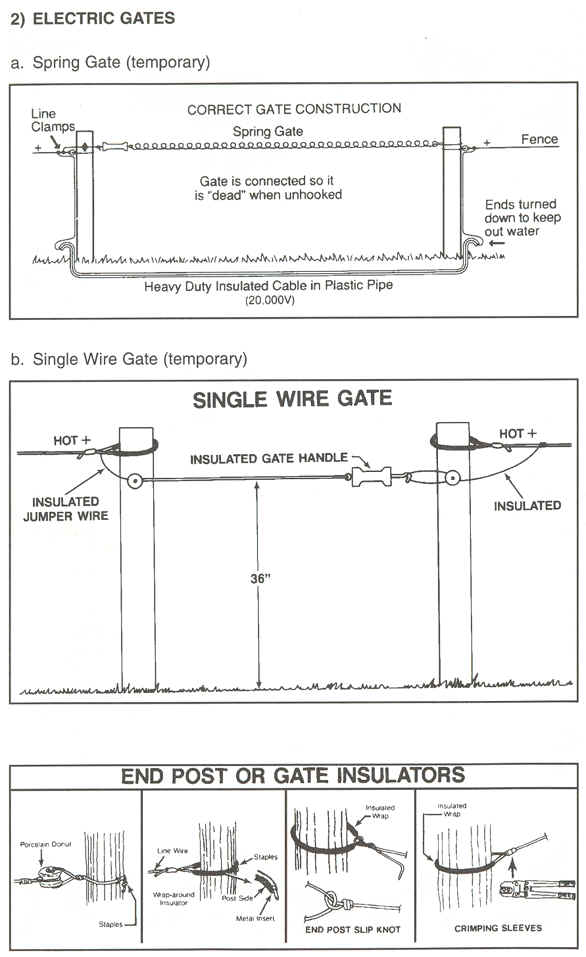

STEP 1

Install your fence controller under cover and protect all

electrical connections from moisture. The fence controller

lead-out wire carries voltage from the (hot) fence terminal to

the fence. A jumper wire carries voltage from one electrified

fence line to another (i.e., gates, buried wire, corners, and

multiple wire fence systems). Use insulted cable that is

manufactured for electric fencing (10 to 14 gauge wire insulated

to 20,000 volts). Do not use common electrical wiring; it is

only rated for 600 volt use.

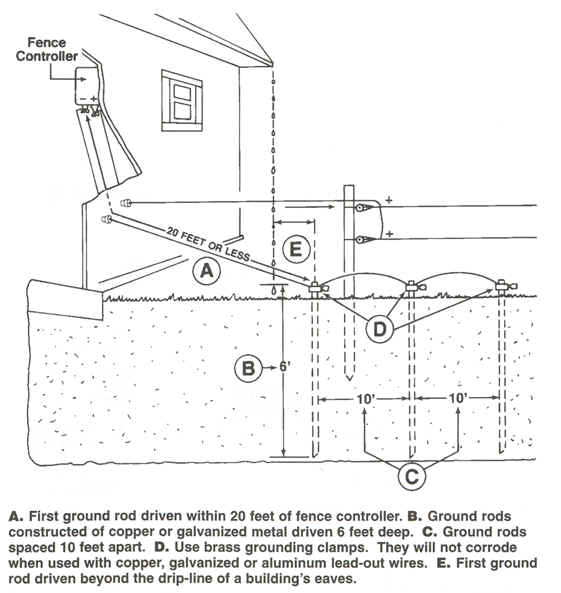

STEP 2

Install at least one 6 ft. galvanized or copper ground rod

within 20 ft. of the fence controller. Use a ground rod clamp to

attach the insulated ground wire to the ground rod (clamp must

bite into rod and ground wire). The ground wire should be 10 to

14 gauge wire and insulated from 600V to 20,000 volts. For best

results, install three ground rods into the earth 6 ft. deep,

spaced 10ft. apart. If possible, install ground rods in areas of

constant moisture.

STEP 3

Do not install ground rods within 50 ft. of a utility

ground rod, buried

telephone line, or buried water-line (they may pick up stray

voltage). This is

evident if you receive pulsing shocks from water spigots or

water tanks or if

you hear the pulse of the fence controller in your phone,

television, or radio.

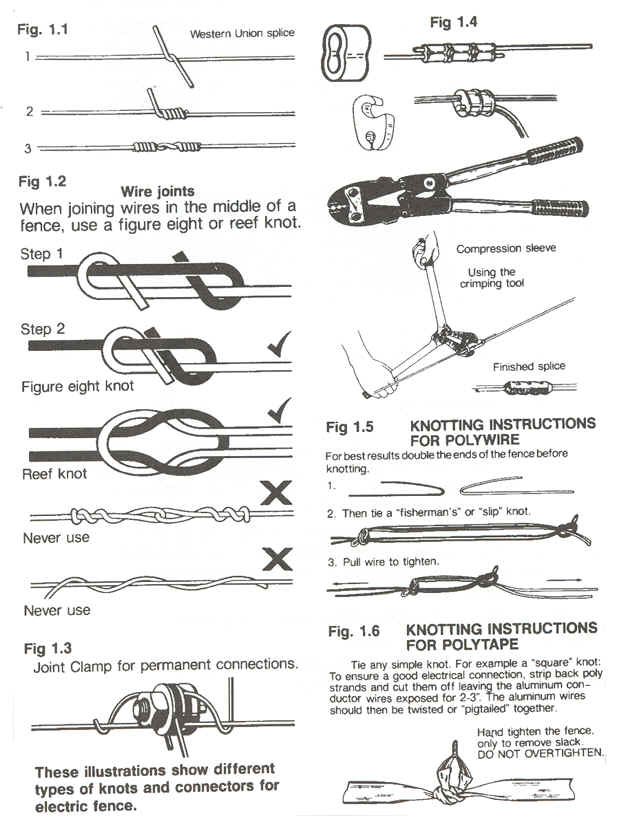

Step 4

Make good connections, using wire clamps, wire connectors, and

proper splices (refer to drawings). Simply wrapping the wire

loosely causes corrosion at the splice and reduces the power on

the fence. Use high quality insulators, gate handles, and

insulator wrap, with UV (ultra violet) inhibitors for your

fence. If using metal fence posts, make sure fence wires cannot

touch the post. There are specific types of wood posts designed

for electric fence use without insulators.

Illustrations of

different types of knots and connectors for electric fence

II.

OPERATING INSTRUCTIONS FOR THE SOLAR POWERED

ELECTRIC FENCE CONTROLLER

The solar powered fence controller eliminates repetitious

battery recharging and replacement and reduces costs by

utilizing free energy from the sun. Its unique design collects

and stores the sun's energy during both sunny and cloudy weather

conditions. It will retain its full charge through 15 days of

total darkness thereby keeping maximum shock on your fence line

at all times.

This completely portable SOLAR POWERED

fence controller is designed for easy installation. The SOLAR

PANEL is mounted at the proper angle to ensure maximum

year-round energy collection. It is IMPORTANT to mount

your unit in a location that receives full sunlight throughout

the entire day and to fasten it securely to prevent turning and

shifting. Its solid state circuit has excellent high/low

temperature characteristics which are unaffected by changes in

the weather for maximum output voltage on the fence wire.

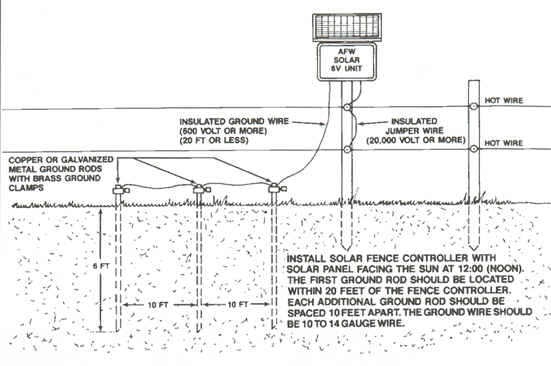

Installing

Your Solar Powered Fence Controller

STEP 1

Face the SOLAR PANEL towards the noontime sun. Due south

in the northern hemisphere.

STEP 2

Connect the lead-out wire to the fence terminal and connect the

ground wire to the ground terminal.

STEP 3

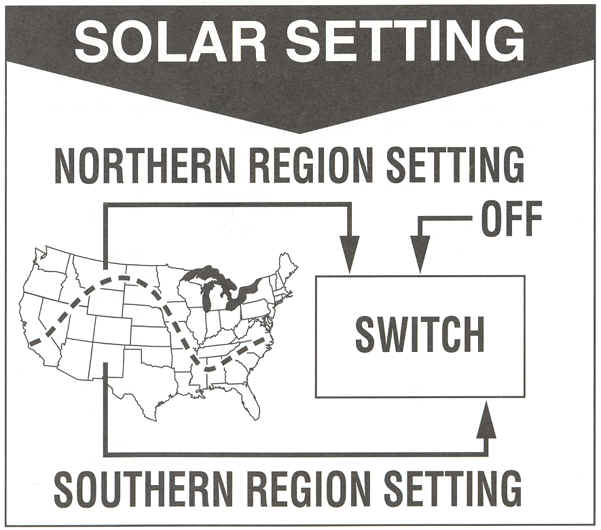

SOLAR REGION SETTING: (For solar fencers that have a solar

setting switch).

Solar fencer installations north of the line

on the solar setting map, have less useable sunlight each day

when compared to installations south of the line.

For optimum performance throughout the year,

installations north of the line on the map should slide the

solar setting switch to the northern region setting (far left

position). Installations south of the line on the map should use

the southern region setting (far right position). If you can't

determine if your installation is north or south of the line on

the solar setting map, use the northern region setting (far left

position). Failure to use the proper solar region setting will

limit the solar fencers battery life and void your warranty.

For solar fencers not equipped with a solar

setting switch, slide the 2 position switch to the on position.

The operating light should flash with each

pulse of electricity that is sent to the fence

FOR BEST PERFORMANCE: After

installing your new solar fence controller, slide the switch to

the "OFF" position. This allows the sun to charge the

solar fence controller battery. Let the solar battery charge for

three full days.

BATTERY MAINTENANCE: Repeat

the above three day charging process each time the fence

controller is placed in storage or taken out of storage. DO

NOT store out of direct sunlight for periods of more

than 3 months without first repeating the battery charging

procedure or the battery may fail.

IMPORTANT:

DO NOT CHARGE THE SOLAR POWERED ELECTRIC

FENCE CONTROLLER BATTERY WITH AN

AUTOMOBILE BATTERY CHARGER. THIS WILL DAMAGE THE BATTERY. A

TRICKLE CHARGER SHOULD BE USED TO MAINTAIN THE BATTERY WHEN THE

FENCE CONTROLLER IS NOT IN USE FOR PERIODS EXCEEDING 3 MONTHS.

CAUTION! DO NOT ALLOW THE BATTERY TO CHARGE OVER 18 HOURS WITH A

TRICKLE CHARGER!

SOLAR PANEL MAINTENANCE: In the instance that battery

replacement becomes necessary be sure to CLEAN the solar

panel. However, under EXTREMELY DUSTY conditions the

solar panel should be cleaned periodically with a soft cloth and

water without detergent or abrasive cleaners. A clean solar

panel will operate at maximum efficiency.

III. HOW ELECTRIC FENCING

WORKS

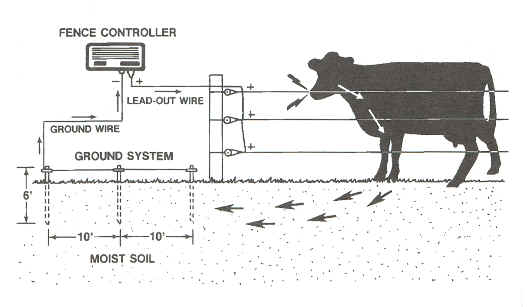

Electric fencing

is a "fear" barrier that uses safe electric shock to deter

animals. In order for an animal to feel a shock, the voltage

produced by the fence controller must be high enough to

penetrate the animal's hair, hide, and hoof. Once the voltage is

high enough to deliver a shock, electricity must travel through

the fence wire. It then flows through the animal that is

touching the fence and into the soil the animal is standing on.

The electricity then travels through the moist soil back to the

ground rods. From the ground rods the electricity flows through

the ground wire that is attached to the fence controller's

ground terminal. The circuit is completed and the animal feels

the shock instantly.

A good ground

system will pick up most of the electricity conducted by the

animal and send it to the fence controller. Poor grounding can

cause interference on telephone lines, in radios, and on

televisions. You may also receive a shock from metal cased

fence controller or ground rod when it is not grounded properly.

In

very dry climates (dry sandy soil) and cold climates (snow

covered or frozen soil) an alternative fence installation must

be used. This fence system implements

the use of a ground wire running parallel to your hot wire. This

ground wire should be grounded every 1,300 ft. with 6 ft.

galvanized

steel

or copper ground rods. This fence installation is no longer

dependent on good soil conditions and will carry the electricity

back to the fence controller's ground system when livestock

contact the hot and ground

wires

simultaneously.

IV. TROUBLE SHOOTING YOUR

ELECTRIC FENCE

Even the best-built electric fences have problems from time to

time. The best time to discover and fix the problem is before

your livestock get loose. Use a volt meter designed to test an

electric fence or a five light fence tester to check the fence

every day. When the voltage drops drastically (Remember:

Although wet insulators from rain or snow will cause fence

voltage to drop, the proper fence controller with correct

installation techniques will perform satisfactorily) take the

following steps. . .

STEP 1

FENCE CONTROLLER DOES NOT OPERATE, CHECK THE

FUSES

| a.

|

Some fence controllers

do not have fuses. Replaceable fuses can be replaced if

there are fuse holders located on the exterior of the

fence controller cabinet. |

| b.

|

If fuses are blown,

replace them with "1 amp/250V" fuses. Plug the fence

controller in. If the fuses blow instantly the fence

controller must be serviced. Should the fence controller

operate for several hours before blowing a fuse there is

a problem with your fence installation, go on to Step 2. |

| c.

|

If fuses are O.K. and

the fence controller does not operate, go on to Step 2 |

STEP 2

CHECK THE POWER SOURCE: Unplug the fence

controller or disconnect the battery clamps from the battery,

before checking power source.

| a.

|

A fence controller that

operates on 115VAC must have a power source ranging from

105VAC to 125VAC. |

| b.

|

A 12 volt battery fence

controller should have a power source of 12 volts

minimum when testing. |

| c.

|

The 6 volt or 6/12 volt

battery fence controllers should have a power source of

6 volts minimum when testing. |

|

Note: for best results

use a deep cycle battery rated at 85 amp hrs or more. |

STEP 3

CHECK THE FENCE CONTROLLER FOR OUTPUT: Use

a volt meter designed to test electric fence controller output.

Ask your local farm store for this product.

If a volt meter is unavailable you can use a

screwdriver as a "gross check" for voltage output. Disconnect

the hot lead-out wire from your fence controller. Do not remove

your ground wire. Using a screwdriver with an insulated handle,

draw an arc between the hot terminal and the ground terminal.

The length of the spark gaps are listed below for your use. This

is not an accurate method to test your fence controller, but it

will indicate whether or not your fence controller's output is

reasonable.

-

The 115VAC solid state fence controllers have

a typical spark gap of 1/8 inch to 1/4 inch

-

The battery & solar fence controllers have a

typical spark gap of 1/16 inch to 3/16 inch

-

The weed chopper fence controllers have a

typical spark gap of 1/32 inch to 1/16 inch

-

The continuous current fence controllers have

a typical spark gap of 1/32 inch to 1/16 inch

If the fence controller output is low your fence

controller should be serviced. If the output is O.K. go on to

Step 4.

STEP 4

IF THE FENCE CONTROLLER OUTPUT AND POWER SOURCE

ARE NORMAL, CHECK THE FENCE INSTALLATION

| a. |

Reconnect the hot

lead-out wire (which was disconnected in Step 3) to the

fence terminal. Then disconnect the lead-out wire at the

fence and check for voltage. If the voltage is good the

lead-out wire is O.K. If the voltage is low, you must

replace the lead-out wire. Use AFW hookup wire

rated at 20,000V. Go on to Step 4b. |

| b. |

Reconnect the lead-out wire and

disconnect all fences that run off the main fence and

check the voltage. If the voltage is low, the problem

lies in the main fence. If the voltage is O.K.,

reconnect fences, checking voltage as each fence is

added. Voltage should remain steady or show a slight

drop until you connect the fence causing the problem.

Then the voltage will drop drastically or the fence will

short out completely.

|

| c. |

Once you determine which

fence or section of fence is causing the problem, walk

the fence line looking for shorts. Look carefully at

corners and gates, and where the fence comes close to

other fences. Pay close attention to insulators and

connections, listen for telltale snapping sounds that

indicate electrical shorting. |

| d. |

Vegetation or rust on the fence is the

most common cause of voltage loss. Even high-power, low

impedance fence chargers lose voltage when enough weeds

and grass touch the fence (especially when wet).

Spraying herbicide under any type of fence is good

management, particularly under electric fence. Rust on

the fence wires acts like an insulator and will not

transfer the electric shock to the animal. If your fence

wire is rusty replace it. |

V. RADIO AND TELEPHONE

INTERFERENCE:

-

The fence controller ground system must be

sufficient-see grounding illustration.

-

The fence controller ground system must be at

least 50 ft. away from the utility ground and buried water

pipes.

-

The fence controller MUST NOT be

connected to the AC utility ground rod or water pipe.

-

The fence controller ground wire should not

touch buildings which can act as a broadcast antenna. Use

insulated cable (10 to 14 gauge wire insulated from 600V to

20,000V) or high quality electric fence insulators to

isolate the ground wire.

-

Place the fence controller and its ground

system at least 50 ft. away from radios and buried telephone

wires.

-

Avoid running electric fence parallel to

power lines or telephone lines.

-

Use top quality insulators. Poor quality

insulators arc when they crack or become weather checked;

this arcing causes radio interference.

-

To locate shorts, poor splices, broken wires,

and faulty insulators, walk the fence line with a transistor

radio tuned off the station on the AM band and on high

volume. The radio will click louder as you approach an

arcing insulator.

VI. LIGHTNING AND SURGE

PROTECTION

Lightning is one of the main causes of fence

controller failure. There are some precautions you can take

against lightning and AC power surges. Disconnect the controller

from the fence line and power source when storms are near.

(Caution: never disconnect or approach a fence during a

lightning storm.) Install a lightning diverter (commonly

referred to as a lightning arrestor) between the fence and the

fence controller. This will divert the electricity from

lightning strikes induced on to the fence to the earth before it

does any damage to the controller. Lightning diverters do not

arrest or stop the flow of current from a lightning strike, they

direct the flow of current into the ground when properly

installed. lightning diverter, is recommended for all types of

fence controllers.

You can also protect 105-125VAC fence controllers

from electrical surges on the utility side by installing a surge

suppressor. The suppressor is plugged into the outlet and the

controller is plugged into the suppressor. Surge suppressor will

protect from surges up to 6,000 volts and has a response time of

less than 5 nano seconds.

A quick way of disconnecting the fence from the

controller before storms occur would be installing an Cut Off

Switch. It also makes it convenient for working on a fence line.

You don't have to unplug the fencer at the power source.

Using these types of protection will minimize the

possibility of your controller being damaged from lightning or

power surges, but if you live in an area of frequent electrical

storms be sure to have a spare fence controller as a back up.

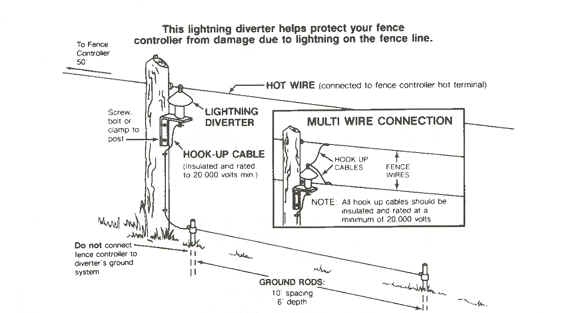

LIGHTNING DIVERTER

INSTALLATION

This lightning diverter helps protect your

fence controller from damage due to lightning on the fence line.

INSTALLATION

| 1.

|

For a single wire fence,

connect the lightning diverter to the fence wire before

mounting on to the fence post. Unscrew the top nut from

the lightning diverter, removing the washer and nut.

Position the lightning diverter against mounting post

with the fence wire passing through the split nut at the

top of the lightning diverter shield. Tighten the top

nut ensuring that the fence wire is not strained. Then

secure the lightning diverter to the fence post. |

| 2.

|

Where more than one

fence wire is hot, first mount the lightning diverter on

to the fence post before connecting hook up cables

(rated to 20,000 volts) to each of the hot wires using

line clamps. Unscrew the top nut and pass the hook up

wires through the split nut and tighten to secure. |

| 3.

|

Connect ground wire by

attaching hook up wire to bottom nut by winding in a

clockwise direction and securing nut. Attach other end

of hook up wire to ground system with ground clamps.

Diverter ground system should consist of a minimum of

two 6-ft. ground rods spaced 10 feet apart and 50 feet

from fence controller ground system. |

| 4.

|

For greater protection, install lightning

diverters on all corners of fence. First lightning

diverter should be installed no closer than 50 ft. from

fence controller.

|

VII.

HELPFUL

FENCE BUILDING HINTS

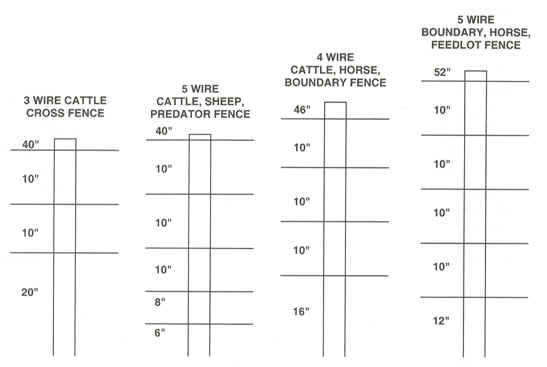

1) PERMANENT ELECTRIC FENCE

SPECIFICATIONS

| a.

|

The number of wires and

the height of a permanent electric fence, aren't as

important as wire spacing. Wires should be spaced closer

together at the bottom of the fence, farther apart at

the top, so animals are shocked on the nose or front of

the head first. The following wire spaces were developed

over many years of trial and error.

As in portable electric fences, the

height of a permanent electric fence is less important

than the wire spacing. Most animals go under or through

permanent fences, rather than jump over them. |

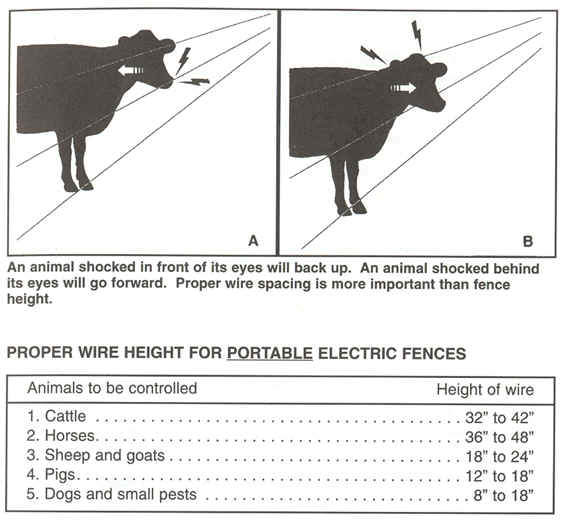

| b.

|

No matter how many

strands your fence has, one hot wire should be

positioned at shoulder height of the animal to be

controlled. This will cause the animal to hit the fence

with its nose first, the area most susceptible to

electric fence shock. If an animal is shocked in front

of its eyes, it will back up. An animal shocked behind

its eyes will go forward into the fence. Proper wire

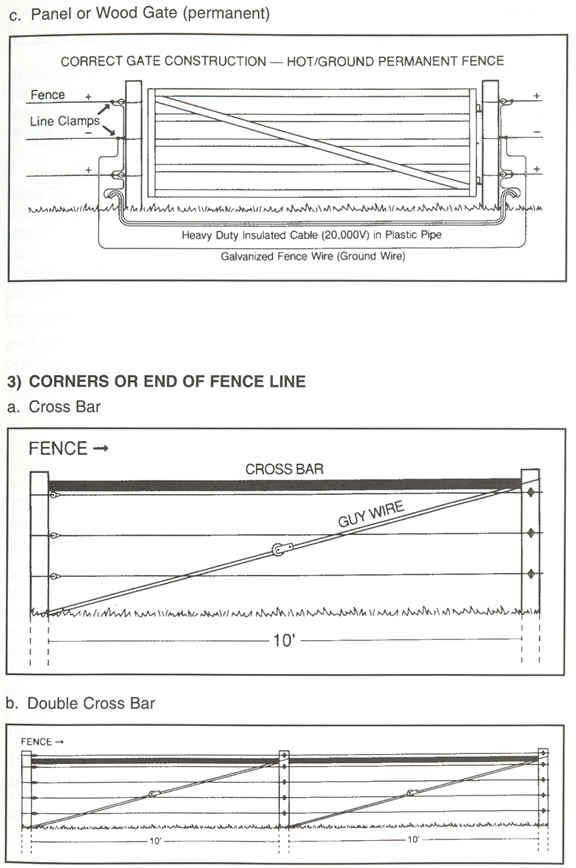

spacing is more important than fence height. |

Since an electric fence isn't a physical barrier, the wire

doesn't have to be stretched (Piano String) tight. But, pull it

taut enough to stay at the same height between posts. Posts

should be spaced every 25 ft. to 75 ft., depending on the

terrain. If you space your post 75 ft. apart you should use

fiberglass battens to keep your wire spacing the same height

between the post.

Don't try to evenly space posts; in level terrain

posts can be spaced farther apart. In uneven terrain, posts need

to be spaced wherever there is a high or low place. On

hillsides, posts should be installed perpendicular to the slope.

This keeps the wire at the proper height and prevents it from

binding on insulators or clips.

|

![]()